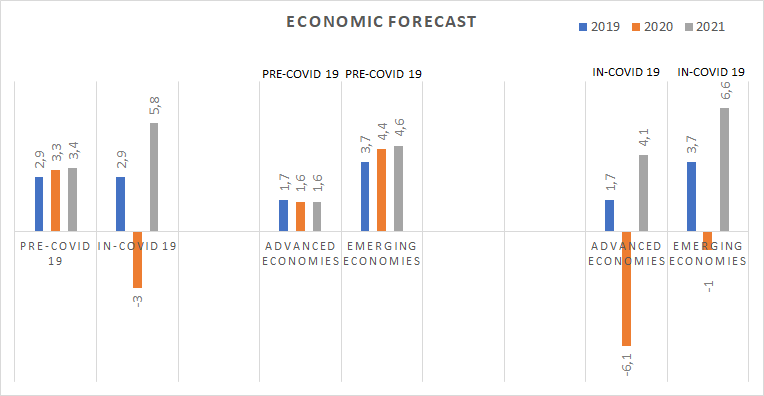

May I for a minute transport your mind to January 2020? The International Monetary Fund (IMF) had forecast that the global economy would grow at the rate 3.3% in the year 2020 and about 3.4 % in 2021. Following the rapid outbreak of the coronavirus; COVID 19, in the months February and March 2020 that forecast was revised by the IMF in an April 2020 report to -3.0% in 2020 and 5.8% in 2021. Keep in mind that these increases are for economic growth and not growth in earnings or transactional profits. Growth here implies increase in economic activities.

China accounts for about 30% of the global manufacturing output. Of the 16 busiest and top revenue generating seaports in the world, 7 of them are located within Chinese territories and 3 of them are among the top 5 revenue generating seaports.

It is no secret, China produces a significant portion of the global consumer goods, machine tools and spare-parts. Therefore it is a delicate decision to either consciously or unconsciously put so much decisive power in the hands of a single entity. It is delicate because should there be operational interruptions in China the rest of the world would be forced into panic mode.

This is exactly what has been happening since February 2020; businesses all over the world have been on emergency mode with severe consequences not just on our ability to manufacture but also on our ability to buy, sell or plan for manufacture.

For the manufacturing sector some of the key lessons that could be taken away from this singular episode are:

An important revelation from the broken global supply chain situation which began in February 2020 is the power of creativity shooting out from across industrial sectors; including from non-traditional manufacturing firms. A creativity driven by scarcity in Personal Protective Equipment (PPE) such as protective gowns, face masks and face shields. Companies that once focused on air-crafts and travels now brought manufacture of face shields to their front-burner while some that made shoes now produce face-masks. These are only a few examples out of scores of companies adapting their manufacturing approaches especially in the advanced economies. At the helm of these leaps in manufacturing is Additive Manufacturing (AKA 3D Printing technologies) suddenly positioned as a critical driving factor. In a straight forward and rapid fashion, 3D Printing has made it possible for companies without the skills-power to operate traditional manufacturing step-up for mask making or ventilator tubes to begin fabricating tens and thousands of items needed to keep citizens safe and alive.

It follows then that 3D Printing technologies can be used to bridge the gap created by a broken supply-chain in the field of manufacturing. For long it has been reported by several qualified studies that Additive Manufacturing technologies offer an alternative gateway to on-shore manufacturing. It will help manufacturers rapidly manufacture in the event that their supply chain is threatened by any unforeseen factor. This seems to be what manufacturing sectors in advanced economies have witnessed within the past 2 months. Teams from the hobby communities and those from professional manufacturing firms reacting to strains within our manufacturing sector by creatively deploying Additive Manufacturing tools.

We need to keep this “iron hot” and shape it into a long lasting form by aggressively educating our manufacturing companies about additive manufacturing, help them create teams that can efficiently work with this technology and push through the concept of digital manufacturing.

Visit us on February 20, 2020 at Steinbeis-Haus, Karlsruhe!

Lectures, workshops and networking

We are looking forward to seeing you!

www.sv-veranstaltungen.de/eos